Who We Are

About Bright Industry International

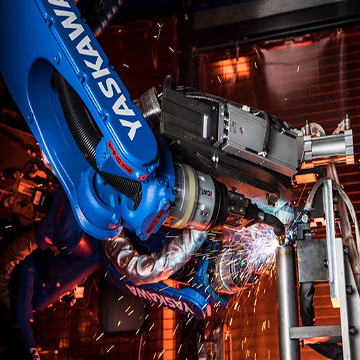

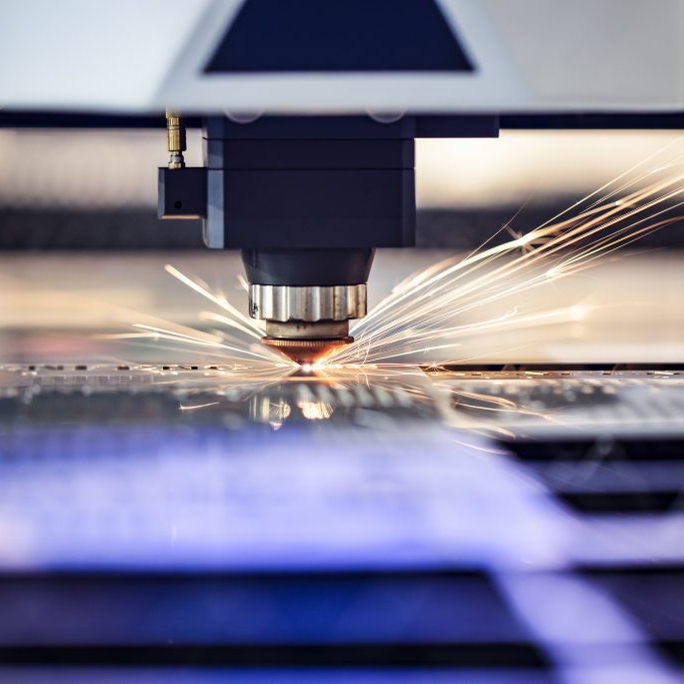

BRIGHT INDUSTRY– Everything for Automation!

Automation equipment and a complete range of automation services in Armenia, Georgia and United Arab Emirates

Services

We provide the complete Automation Services for a wide range of Industries!

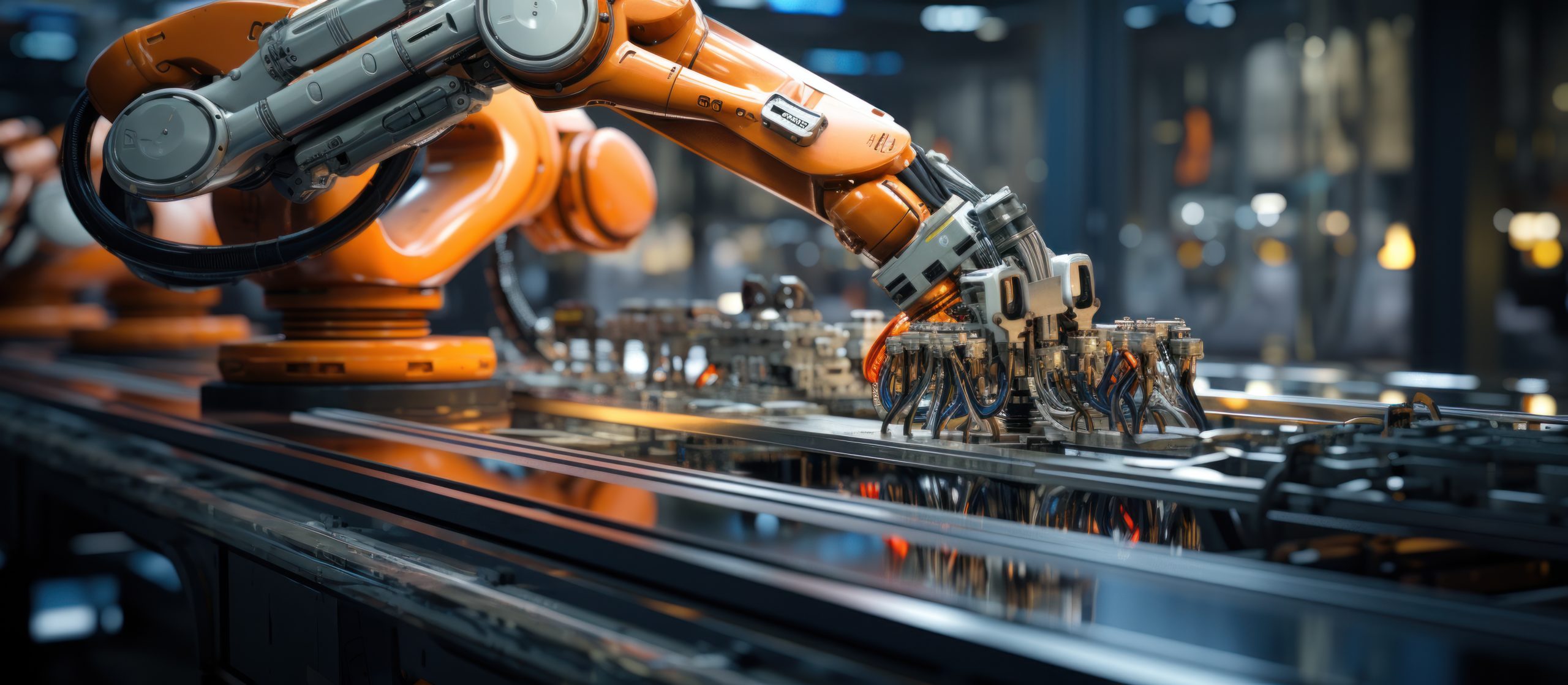

Projects

Over 900 completed projects worldwide

From concept to production, we are committed to developing, building and maintaining quality automation systems that help you reach your goals