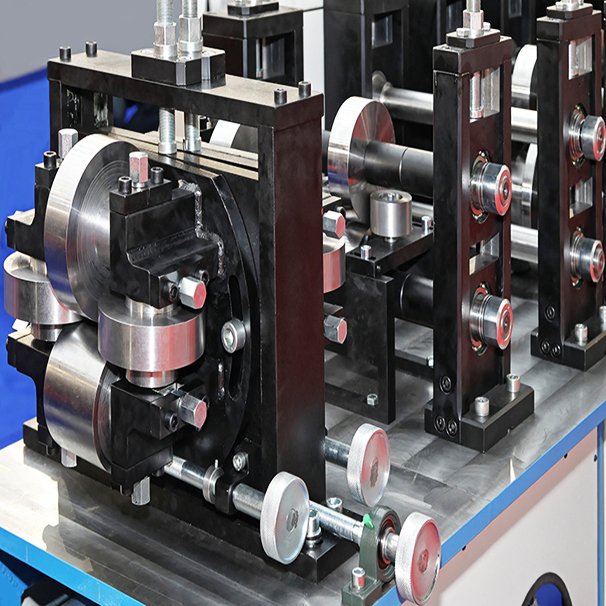

Solutions for all types of Rolforming

Implementation of the functional unit “FLYING”

We offer ready-made solutions of our own design for all types of rolled metal lines (etc. Lines for the production of corrugated board and metal tiles, Lines for the production of building profiles, Slitting lines for rolled metal cutting and cross-cutting rolled metal products, etc.).

Benefits:

- High accuracy due to double feedback

- Compensation of linear backlash

- Remote dispatch of the order for the machine

- Connection to central server

- Connection of additional. devices (e.g. scanner, printer, RFID, etc.)

The additional “FLYING” unit allows for uninterrupted production. The introduction of this unit will increase productivity up to 300%. A servo system works on this unit and all actions (eg punching and cutting) take place in motion, the supply of the metal sheet is continuous. The introduction of the unit is possible on all types of metal rolling machines. A full range of measures to modernize production in order to increase their productivity and profitability.

Armenia

Metal Forming Industry Automation

$100,000

Qualitech Machinery